Real-Time Visibility. AI-Powered Insights. ROI in 30 Days.

BEET Core 5.0 is the fastest way to digitize your operations and empower your workforce with intelligent performance insights – no sensors or complex IT required.

Who benefits from BEET Core 5.0?

- Manufacturers connecting fewer than 200 assets

- Teams who want fast, out-of-the-box value with minimal setup

No in-house developers needed – BEET comes pre-configured with everything you need to get started.

Wondering which solution is right for you?

Compare BEET Core 5.0 with Enterprise to find out the best fit.

Reveal Your Line’s True Capacity With Process Potential

Most manufacturers operate well below their lines’ capabilities.

BEET analyzes your normal production data to identify your top 10% of repeatable cycle times – so you can stop treating capacity as fixed and start improving based on what’s actually achievable.

You don’t need more machines. You need better visibility into the machines you already have.

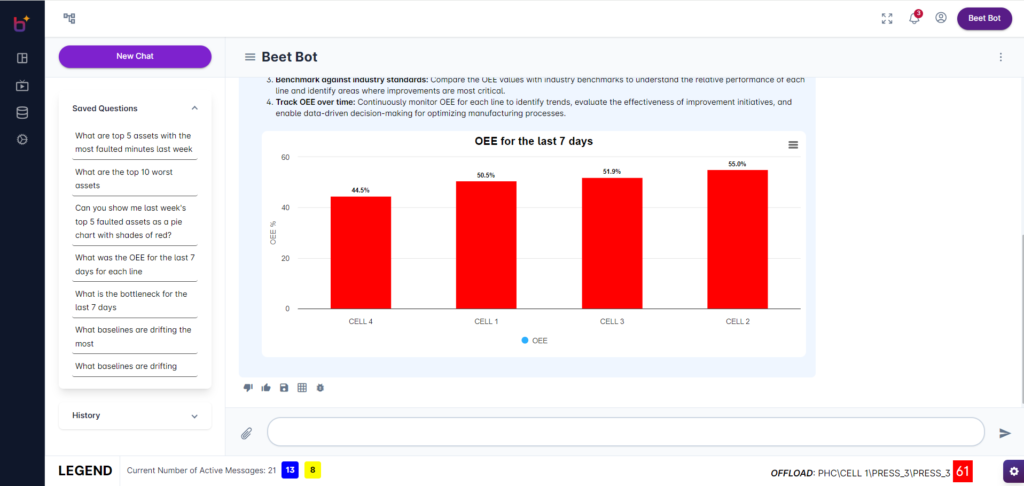

BEET Bot

AI Copilot for Real-Time Operational Insights

As a manufacturer committed to consistently delivering on KPIs and ensuring that your people, process and equipment are working in harmony, BEET Bot is your new best friend. A large language model powered by Google Gemini, BEET Bot provides powerful insights through natural language queries.

Live Line Intelligence

Total Visibility Into Every Second of Every Cycle

BEET delivers high-fidelity, real-time production data down to the device level, enabling teams to spot inefficiencies, pinpoint bottlenecks and optimize performance – without polling or added sensors.

BEET Home Page

Your Gateway to Operational Excellence

BEET’s highly customizable and interactive Home Page dashboard enables real-time monitoring and data visualization, providing a single pane of glass for your operations.

A Real-World Example

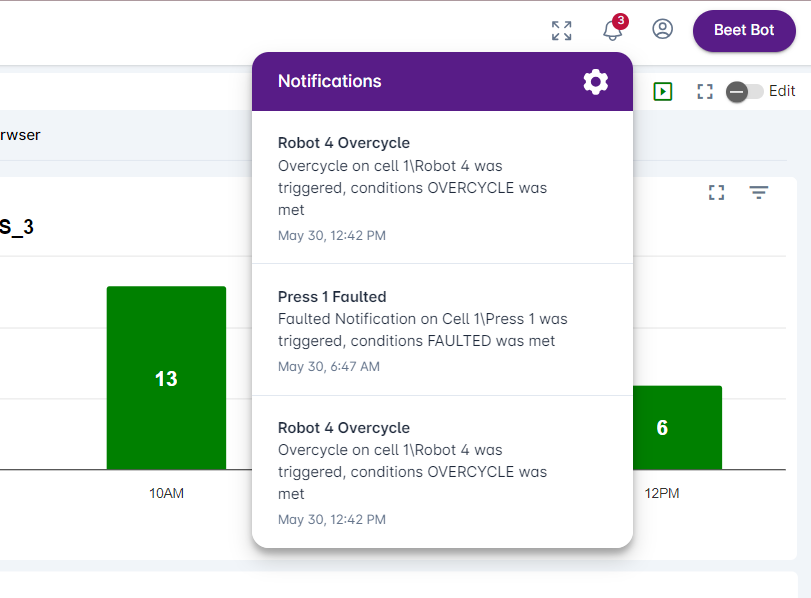

A maintenance supervisor could set up an alert to trigger when a CNC machine experiences more than 5 minutes of downtime. Once this condition is met, the system will automatically send a notification to the relevant team members via their preferred communication method (text, email or system notification), prompting them to take corrective action.

Conditional Alerts

Automate Notifications for Immediate Response to Critical Events

Use BEET’s Conditional Alerts feature to set up automated notifications based on specific criteria, enabling a proactive response to important events.

Webasto Group

Discover how Webasto Group, a global leader in automotive technology, increased throughput and reduced unplanned downtime with the BEET Platform.