Table of Contents

By Mike Minelli

In automotive manufacturing, real-time production alerts aren’t just helpful—they’re essential. Every minute counts, and when issues like cycle time deviations or faulted equipment go undetected, throughput drops. By the time it shows up in a shift report, Jobs Per Hour (JPH) is already down—and recovery is harder.

The problem isn’t effort or technology – it’s timing. You can’t act on a problem until you know it exists.

Why Automotive Manufacturers Lose Throughput They Could Recover

A 20-minute issue on a bottleneck line can derail takt time for the entire shift. But in most facilities, line leads and engineers don’t find out about it until hours later.

This isn’t just anecdotal. Recent research shows that real-time monitoring can increase production efficiency by up to 20%, largely by enabling faster response to deviations in cycle time, asset utilization, or coordination between zones.

Unfortunately, traditional systems aren’t built for in-the-moment clarity. MES and SCADA platforms surface performance data — but not fast enough to influence what’s happening on the line right now.

BEET Enables Real-Time Action – Without Additional Equipment

BEET integrates directly with your existing PLC infrastructure, extracting live signals from your line without requiring new sensors or hardware. Our platform converts that data into asset-level intelligence, making it available in real time to the people who need it.

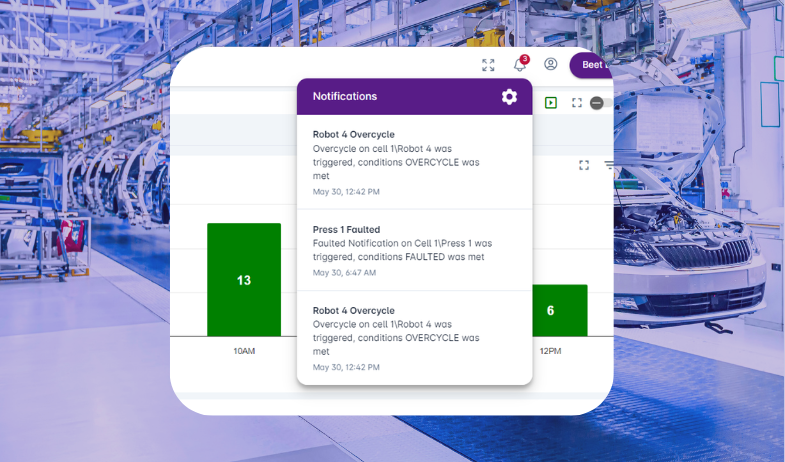

When a line falls out of takt (the ideal pace of production required to meet customer demand), BEET can trigger precise alerts based on your team’s defined thresholds. These could include conditions like overcycle time, faulted press states, or starved equipment. Real-time production alerts are routed immediately to the right roles—before productivity slips further.

Example:

🚨 Cycle Time Exceeded – Line 2, Framing Cell B

📤 Sent to: Shift Lead, Maintenance, CI Engineer

No manual checks. No control room bottlenecks. Just fast, informed action from the people closest to the problem.

From Dashboard to Decision in Seconds

Dashboards are helpful, but they’re passive. They’re designed for monitoring, not momentum.

Real-time alerting creates a closed-loop system:

- A deviation is detected instantly

- An alert is sent to the responsible team

- The issue is addressed within the shift

- Throughput is preserved, not reviewed after the fact

Plants that adopt this approach reduce their dependency on retrospective analysis—and protect their output in real time.

Empowerment on the Line: A Cultural Shift

In successful OEMs, high throughput isn’t just a function of automation. It’s the result of high-performing teams who can act without waiting for direction.

When operators and supervisors have access to the same real-time insights as engineering and CI, they can:

- Fix issues before they escalate

- Reduce unnecessary escalations

- Align around data, not assumptions

This builds a culture of ownership on the floor – and it changes how every team member approaches their shift.

If You Catch It Mid-Shift, You Can Still Recover

Manufacturers often think improving throughput means adding equipment. In reality, many lines have untapped potential – they’re just lacking the visibility to unlock it.

With BEET, automotive plants gain real-time alerting layered onto their existing controls, empowering teams to act faster, protect throughput, and meet takt targets with confidence.

Every alert caught mid-shift is a unit recovered.

Each decision made in real time is capacity protected.

Every minute matters.

Want to protect throughput without adding new equipment?

Talk to our team about how BEET can connect to your PLCs, deliver real-time alerts, and help you recover more units per shift—starting this quarter.