In this session, we will dive into how the Internet of Things (IoT) is transforming the manufacturing landscape. IoT-enabled devices offer real-time data collection, giving manufacturers the tools to unlock actionable insights that drive operational efficiency, enhance production processes, and minimize downtime.

Discover how a Tier 1 automotive component manufacturer leveraged IoT to achieve remarkable results, including:

- 1-10% increase in Overall Equipment Effectiveness (OEE)

- 15-20% improvement in throughput efficiency

- Over 25% reduction in unplanned downtime

Don’t miss this opportunity to learn how IoT is shaping the future of manufacturing!

Key Discussion Points from the Webinar:

- Core Technology and Infrastructure

- What role does IoT play in enabling Industry 4.0 within modern manufacturing environments?

- How to integrate legacy systems with IoT solutions—challenges and strategies.

- Data-Driven Decision Making

- Real-time data collection: How can IoT improve operational visibility and efficiency?

- From raw data to actionable insights: The role of AI/ML in IoT-powered production lines.

- Predictive vs. prescriptive maintenance—what’s the ROI on each?

- Business Impact and Scalability

- Measuring ROI: What metrics really matter in IoT implementation for manufacturing?

- Scaling IoT deployments from pilot to full-scale operations—best practices and pitfalls.

- Real-world case studies: Lessons from manufacturers who’ve successfully transformed using IoT.

- Q&A

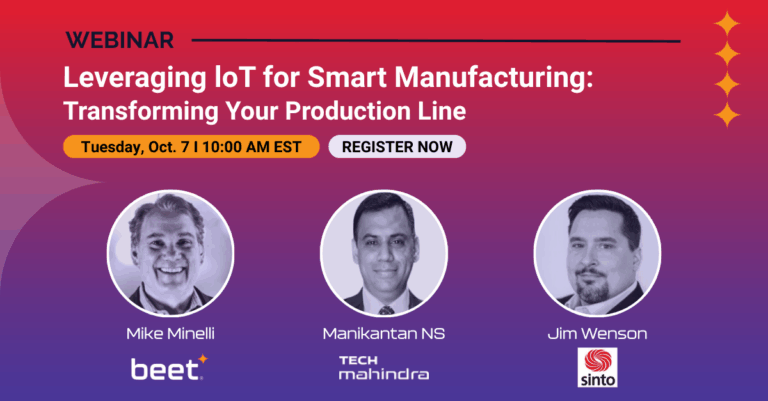

Our Speakers

Recommended

Case Study

Webasto Group: a Global Leader in Automotive Technology

Discover how BEET helped Webasto improve OEE and throughput.

BEET Core 5.0

The Future of Intelligent Manufacturing is Now

BEET Core 5.0 with GenAI: The future of Intelligent Manufacturing is here.

Blog

A Webinar Recap: The Role of GenAI in Mfg

sajhfahjfajnnjkf sjksfhkjhkj sfjh sjfhs jhfsjfh jkfhkjfhkefh ekjhfskkjhdf sfjhsf sjfgf sf.