Combines out-of-the-box intelligence with flexible customization.

Wondering which solution is right for you?

Compare BEET Core 5.0 with Enterprise to find the best fit.

ERP, MES and SCADA systems weren’t designed to deliver real-time, device-level insight. BEET Enterprise fills that gap, capturing motion-level data directly from your factory floor and layering it with AI and analytics to reveal what’s actually happening, right now.

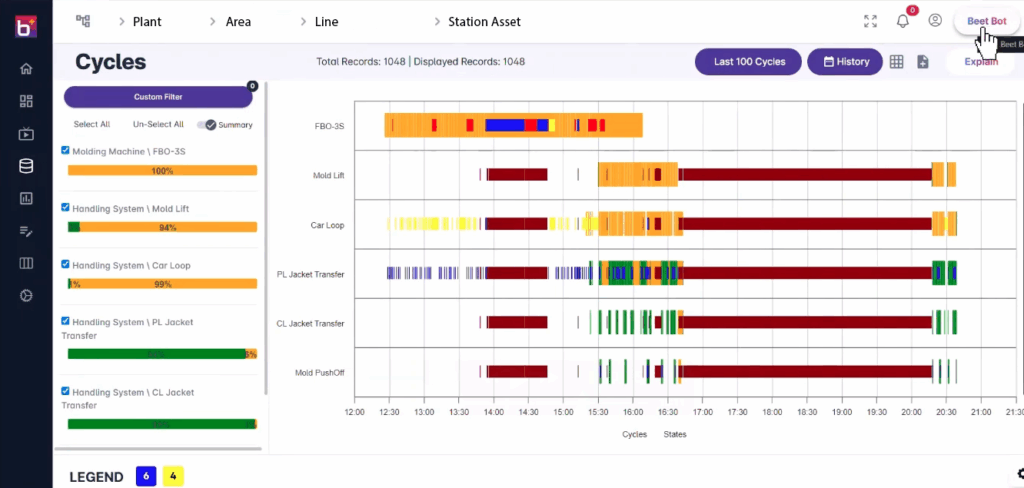

Pinpoint the exact bottlenecks holding your line back. Understand where seconds are lost – and where they can be gained to increase jobs per hour (JPH). Prioritize improvements with confidence, not guesswork.

You don’t need to rip and replace your systems. You need a layer of intelligence that works with them.

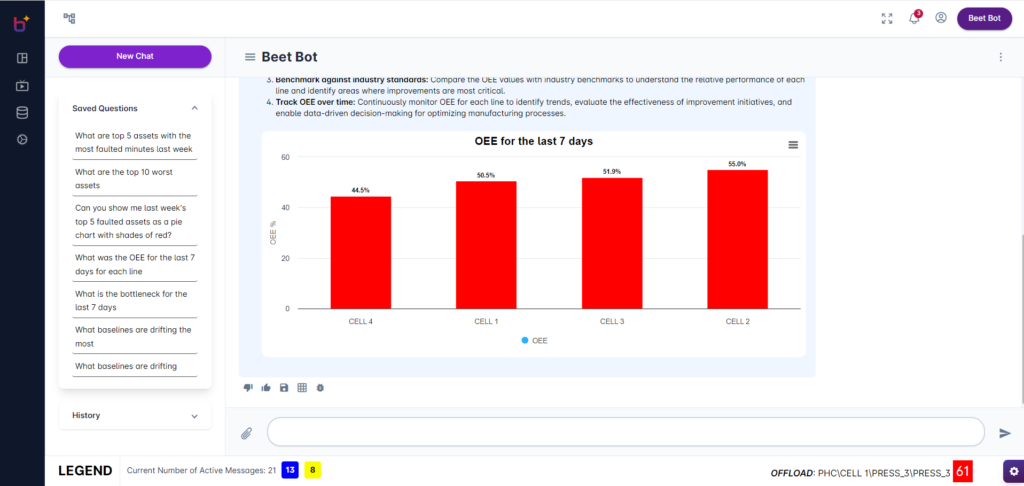

Powered by Gemini, BEET Bot gives teams instant access to real-time insights, performance trends and root cause analysis – just by asking.

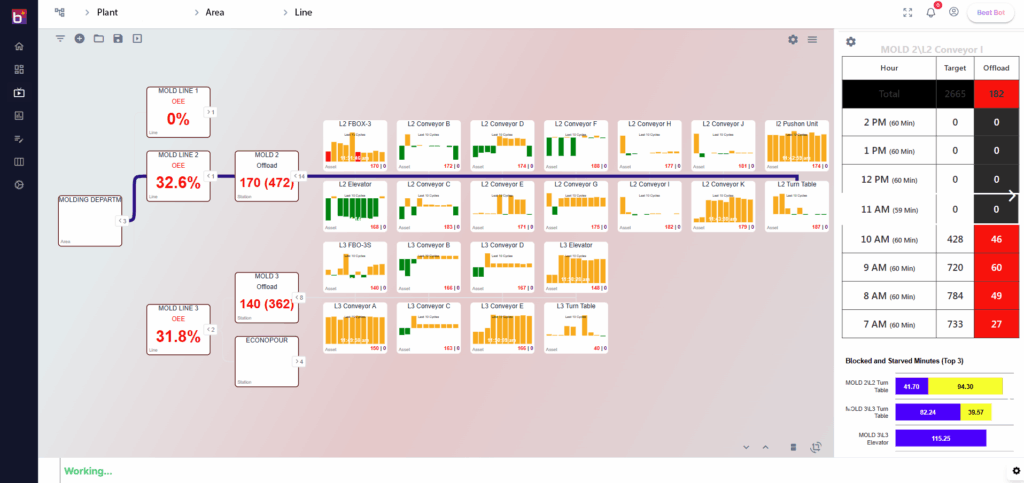

BEET Enterprise gives you deep, device-level analytics across all lines – so you can spot inefficiencies, pinpoint bottlenecks and improve performance with confidence.

BEET Enterprise enables large manufacturers to monitor and manage performance across plants, installations and lines. With flexible configuration, global and personal views, and live data, your teams get exactly the insight they need.

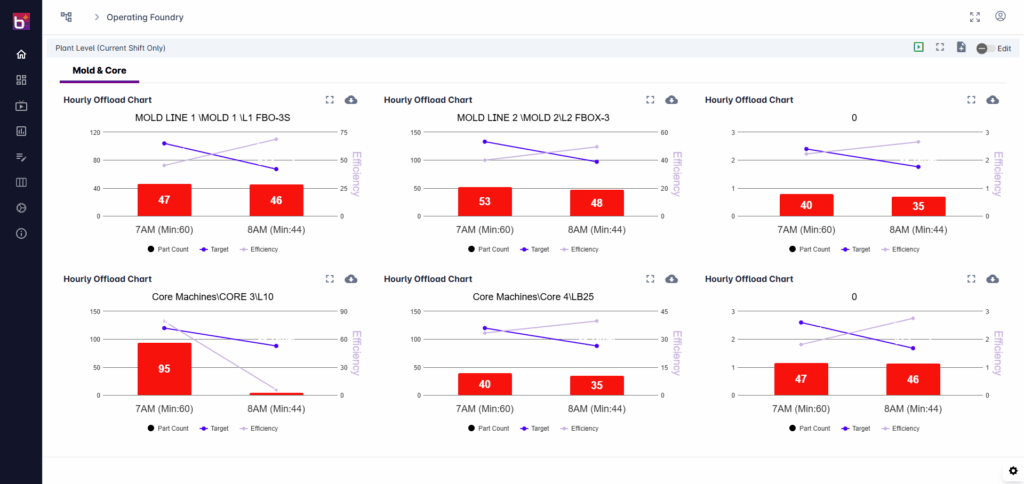

Quickly filter data by current or completed shifts to analyze performance and downtime by shift.

BEET Enterprise’s Data Browser includes three modules – Cycle, Message and Analog – designed to help you analyze trends, identify root causes and optimize performance over time.

View production cycles across lines and shifts, with adjustable historical windows up to 90 days.

Visualize continuous variables like temperature, flow or pressure – ideal for spotting performance drift before it becomes an issue.

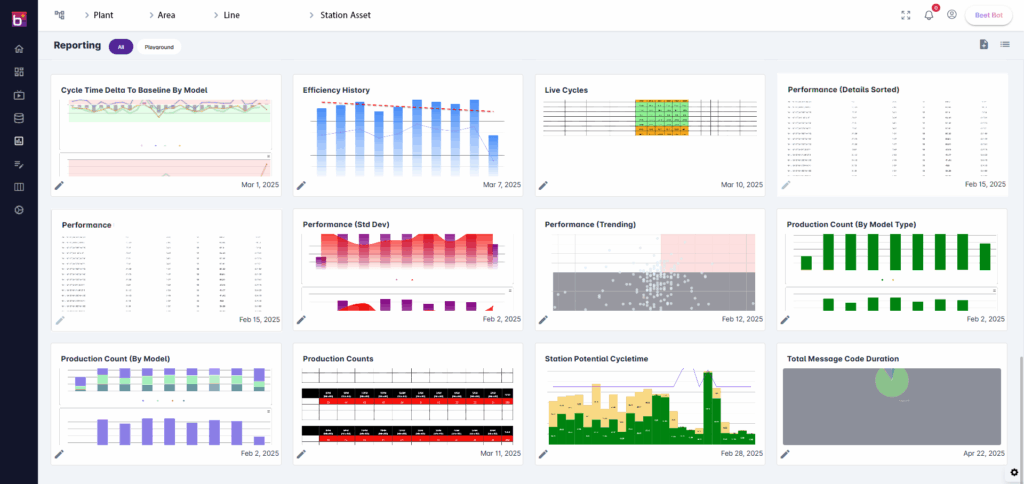

From daily performance to lowest-performing assets, BEET Enterprise provides standard and customizable reports that empower teams to make informed decisions fast.

Includes templates like Top 3 Worst Assets, OEE Trends and Downtime Analysis.

Keep dashboards live with data refreshing at set intervals.

Built-in transparency shows logic, source and report rationale – helping build data literacy across teams.

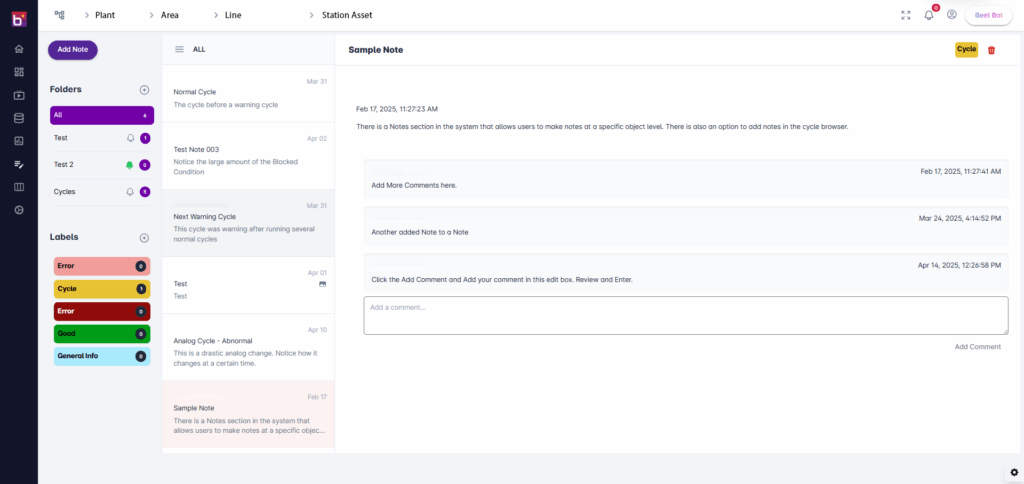

Record operator observations, shift comments and insights that don’t fit neatly into a report.

Organize notes by site, line or topic.

Screenshots, PDFs or logs for full context.

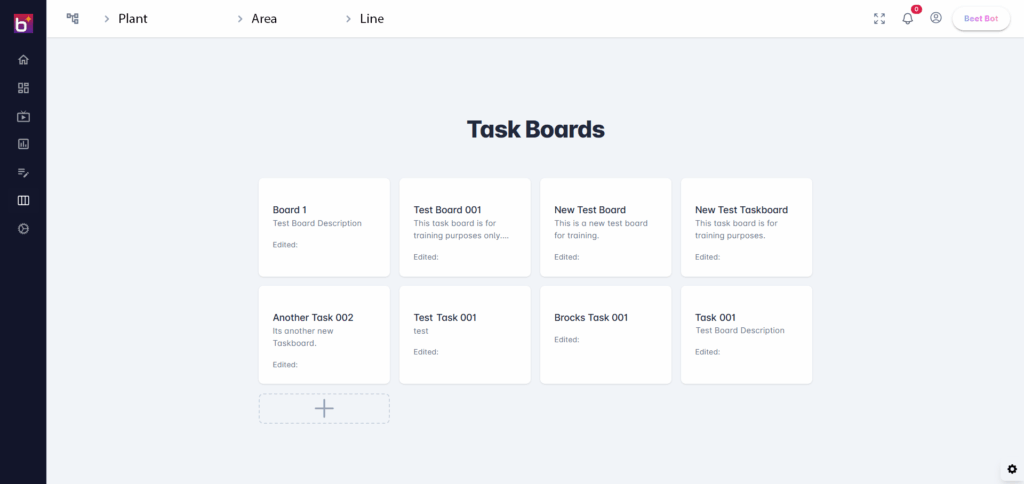

BEET’s built-in task board helps teams assign, track and complete routine and corrective actions with ease.

Drag-and-drop tasks across To Do, In Progress and Done columns.

Keep task boards clean without losing history.

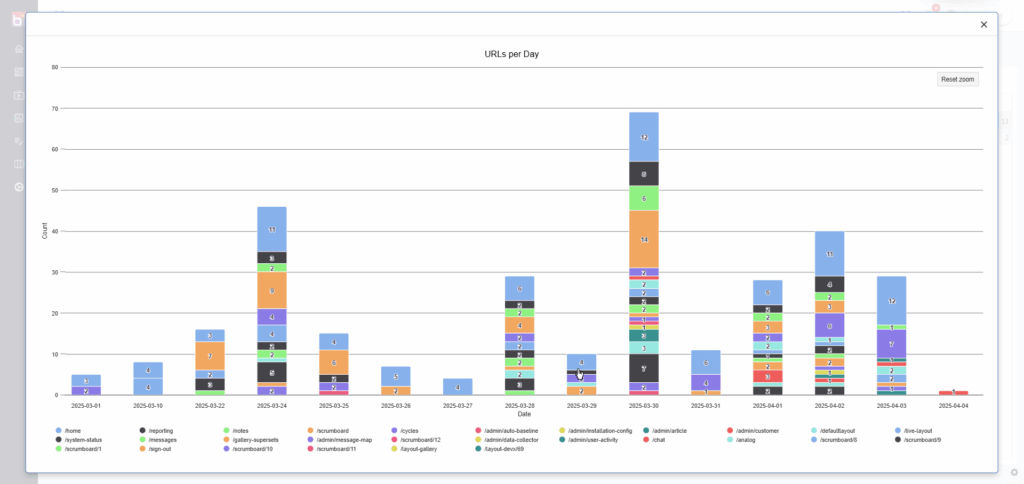

BEET Enterprise puts the power in your hands, giving administrators flexible control over multisite operations, data sources, users and reporting. Manage complex environments with the precision and scalability that today’s manufacturers require.

Easily manage plants, installations and connected assets through a scalable hierarchy. Navigate global operations or drill into a specific line in seconds.

Define roles, permissions, and system settings to keep your operations secure and efficient. Empower the right teams with the right visibility.

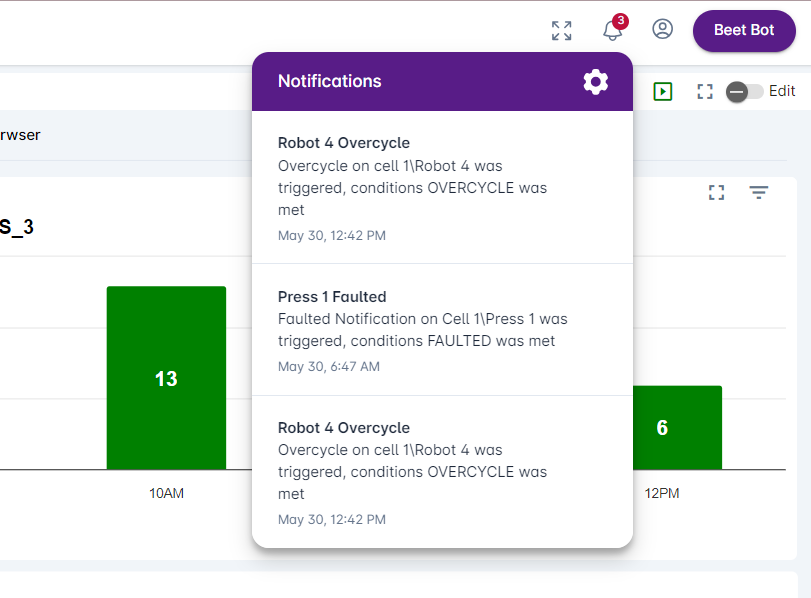

Use BEET’s Conditional Alerts feature to set up automated notifications based on specific criteria, enabling a proactive response to important events.

Discover how manufacturers can extend Industry 4.0 beyond the four walls of the plant — creating connected ecosystems that deliver real-time insights and drive intelligent, agile operations.